Showroom

Under this range of products, we manage a large stock of Ultrasonic Testing Equipments designed to aid in the field of ultrasonic testing. UT or ultrasonic testing is nothing but a non-destructive testing (NDT) where high frequency sound waves are put to use for gauging the exact hardness, thickness, etc., of a particular material that is tested. Materials tested may range from alloys, plastics to composites and ceramics. As such, our selection of Ultrasonic Testing Machines can be used for analysing and detecting a range of flaw and defects, including cracks and leaks in these materials. With such precision and accuracy in operations, these equipment enjoy wide demand in the fields of material testing & engineering, equipment state/condition monitoring, production quality control, and building & bridge inspection among others. For any queries related to the range, please contact us immediately.

There is a high demand of Radiography Equipments in imaging rooms of radiology departments and in pathology departments. With our range, we have lent a modern face to healthcare facilities performing X-ray imaging. Our equipment deliver significant cost savings, also delivering optimum image quality and giving quicker diagnostics. Giving rapid return on investment, Radiography Equipments offered from our end are hi tech, efficient and feature optimum service life. We deal in an extensive assortment of equipment related to radiology and we can tailor machines for every kind of budget, space, etc., i.e., apart from being offered at low cost, our equipment can be easily integrated with any kind of work environment. Our equipment fabricated in sync with modern day clinical and ergonomic workflows in imaging rooms promise to give maximum patient comfort too.

Our finest selection of Eddy Current Testing System offered under this category are setting new excellence benchmarks in the domain of eddy current testing. Lets begin by getting an overview on eddy current testing which is a testing method widely employed across various manufacturing and service settings for conducting numerous testing procedures. Various safety as well as quality related issues can be analysed and detected using such testing methods. The tests can detect crack in metal sheets and tubing. In the aerospace industry, Eddy Current Testing Device can help in certain metal thickness measurements, especially in detecting corrosion under aircraft skin alongside gauging the thickness of non conductive coatings over various conductive substrates. For catering to an exhaustive variety of test methods, we present systems in different configurations and specifications.

We as unrivalled champions in our field design and fabricate a line of Magnetic Particle Inspection Equipments (MPI equipments) that can be fitted onto various industrial environments for giving fast and reliable testing performance. These Magnetic Particle Inspection Equipments are constructed in sturdy and durable bodies that can be availed in different outputs like AC, half-wave DC and full-wave DC. Our range of MPI equipment can be sized for specific test parts by our expert technicians and engineers. We fabricate these equipments keeping needs of modern day testing and evaluation in mind. As such, these MPI Equipments are designed for facilitating easy detection of various defects including surface cracks and fatigue cracks in a range of ferrous materials, such as steel, iron, etc. Defects can be usually detected through the wet or dry method mag particle testing.

Ultrasonic testing machines are highly utilized in the medical sector. The machines use the ultrasonic waves for the testing or diagnosing the diseases by detecting the failures of the body parts or by heating applications.

Radiography Testing Machines, in sleek black metal, cater to industrial needs with precision. Their specific features include high-resolution imaging for flaw detection in materials. Advantages lie in non-destructive testing capabilities, ensuring thorough examination without compromising integrity. Widely applied in manufacturing, construction, and aerospace industries, these machines play a vital role in quality control, enhancing safety, and reliability.

Radiation Monitoring Instruments, designed for industrial use, operate on electric power. Available in various colors, sizes, types, and models, crafted from Mild Steel or ABS. Their applications span industries, providing real-time radiation data. Features include diverse models for different settings, ensuring safety. The advantages lie in their versatility, precision, and contribution to workplace safety through continuous monitoring.

Industrial Radiation Monitoring Devices, weighing 3 kilograms, operate on electric power. Compact in size (250mm x 220mm x 70mm), they are crafted from durable Mild Steel or ABS, with a vibrant yellow color. These devices ensure workplace safety by providing real-time radiation data, making them essential for industrial settings where precision and reliability are paramount.

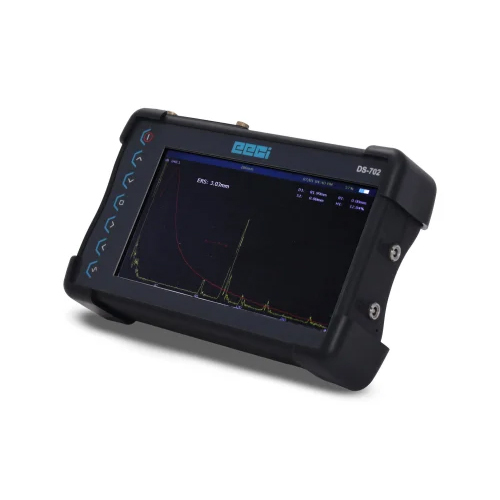

Ultrasonic Flaw Detectors, designed for industrial use, weigh 1 kilogram and come in a sleek black color. Compact at 205mm x 130mm x 60mm, they offer high-frequency sound waves for precise flaw detection. Advantages include portability and real-time imaging, contributing to efficient on-site inspections. Widely used in manufacturing and construction, these detectors enhance quality control by identifying structural imperfections.

The black-colored Hardness Tester, weighing 320 grams, is tailored for industrial use, with a specimen size of 164mm x 86mm x 23mm. It offers precise hardness measurements, ensuring material quality. Advantages include its lightweight design for on-site inspections, user-friendly interface, and widespread industrial applications, promoting quality control in manufacturing processes and ensuring optimal material strength.

Our Export Countries:

|

Abudabi, UAE Algeria Angola Argentina Armenia Australia Azerbaijan Bahrain Bangladesh Belarus Belgium Bhutan Brazil Bulgaria Cambodia Canada Chile China Croatia Dubai UAE Egypt Ethiopia France Fuji islands Germany Ghana Greece Hong Kong Indonesia Iran Iraq Israel Italy Japan Jordan Kazakhstan Kenya Korea Kuwait UAE Lebanon Libya Macao |

Malaysia Maldives Malta Mexico Mongolia Morocco Muscat Myanmar Nepal Netherlands New Zealand Nigeria Oman Pakistan Philippines Poland Portugal Qatar Romania Russia Saudi Arabia Singapore Slovenia South Africa Spain Sri Lanka Sudan Switzerland Taiwan Tanzania Texas Thailand Tunisia Turkey Uganda Ukraine United kingdom Uruguay USA Vietnam Yemen Zimbabwe |

|

ELECTRONIC & ENGINEERING CO. (I) P. LTD.

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese